Reciprocating Compressor Maintenance And Repairing Service

Reciprocating Compressor Maintenance And Repairing Service Specification

- Spare Parts Replacement

- Included if required

- Emergency Service

- Yes

- Technician Expertise

- Certified with experience in reciprocating compressors

- Service Location/City

- PAN India

- Compressor Type

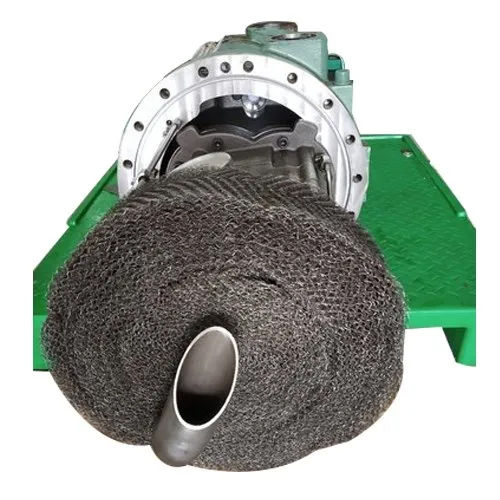

- Reciprocating Compressor

- Downtime Minimization

- Priority scheduling available

- Client Industries Served

- Manufacturing, Chemical, Petrochemical, Oil & Gas, and General Industrial

- Service Type

- Reciprocating Compressor Maintenance And Repairing Service

- Usage/Application

- Industrial

- On-Site Support

- Available

- Service Mode

- Offline

- Equipment Inspected

- Valves, pistons, crankshafts, gaskets and all major components

- After Repair Warranty

- Yes

- Maintenance Frequency

- Customizable as per client needs

- Service Coverage

- Comprehensive diagnostic, maintenance, and repair

About Reciprocating Compressor Maintenance And Repairing Service

Highlighted as a gilt-edged, new release in compressor care, our Reciprocating Compressor Maintenance And Repairing Service delivers supreme on-site support and emergency solutions across PAN India. Servicing manufacturing, chemical, petrochemical, oil & gas, and general industrial sectors, this comprehensive package covers diagnostic, maintenance, and repair of all major compressor components including valves, pistons, crankshafts, and gaskets. Take advantage of priority scheduling to keep your operations soaring and downtime minimized. Certified technicians provide meticulous expertise while spare parts replacement and after-repair warranty ensure reliable performance. Customizable frequency guarantees suitability for all industrial requirements.

Extra Features and Area of Application

Our Reciprocating Compressor Maintenance And Repairing Service offers advanced features such as emergency response, customizable maintenance plans, and on-site inspections. This service is ideal for both specific industrial requirements and general compressor maintenance, ensuring continual peak performance for manufacturing, petrochemical, oil & gas, and chemical operations. Certified technicians apply proven expertise to every task, making this service a robust solution trusted across India's industrial landscape.

Main Domestic and Export Markets, Order Details

Serving both India's domestic industry and international markets, our service caters to chemical, petrochemical, and general industrial clients through key FOB ports. Proposal amounts are clearly communicated to clients, facilitating seamless order completion with transparent expenditure reporting. Comprehensive documentation throughout each service phase ensures client satisfaction and maintains a high standard of process integrity, whether for local projects or export engagements.

Extra Features and Area of Application

Our Reciprocating Compressor Maintenance And Repairing Service offers advanced features such as emergency response, customizable maintenance plans, and on-site inspections. This service is ideal for both specific industrial requirements and general compressor maintenance, ensuring continual peak performance for manufacturing, petrochemical, oil & gas, and chemical operations. Certified technicians apply proven expertise to every task, making this service a robust solution trusted across India's industrial landscape.

Main Domestic and Export Markets, Order Details

Serving both India's domestic industry and international markets, our service caters to chemical, petrochemical, and general industrial clients through key FOB ports. Proposal amounts are clearly communicated to clients, facilitating seamless order completion with transparent expenditure reporting. Comprehensive documentation throughout each service phase ensures client satisfaction and maintains a high standard of process integrity, whether for local projects or export engagements.

FAQ's of Reciprocating Compressor Maintenance And Repairing Service:

Q: How does your service minimize downtime for reciprocating compressors?

A: Priority scheduling and experienced certified technicians allow us to quickly diagnose and repair issues, ensuring minimal disruption to your industrial operations.Q: What components are inspected during compressor maintenance?

A: We provide comprehensive inspection and servicing of all major reciprocating compressor components, including valves, pistons, crankshafts, gaskets, and more.Q: When can clients request emergency maintenance support?

A: Emergency servicing is available 24/7. Clients can contact our support hotline for immediate assistance whenever urgent compressor issues arise.Q: Where is your reciprocating compressor service available in India?

A: Our solutions are offered PAN India, covering manufacturing hubs, chemical plants, and industrial sites across all regions.Q: What does the process of maintenance and repair involve?

A: The process begins with a thorough diagnostic assessment, followed by skilled repair or part replacement if necessary, executed by certified experts, and concludes with quality assurance checks.Q: How does this service benefit industrial clients?

A: Clients benefit from reduced downtime, customized maintenance schedules, certified technical expertise, included spare part replacement, and after-repair warranties, keeping operations efficient and reliable.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Compressor Repairing And Maintenance Service Category

STAR REFRIGERATION SYSTEMS

GST : 27ADWFS9607C1ZJ

GST : 27ADWFS9607C1ZJ

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS